CYCOGS ® brand, Test Equipment, the ACC Chamber

Altitude Control Chamber for Simulations (ACC)

The Altitude Control Chamber (ACC) series is an advanced computer-controlled simulator of atmospheric effects of temperature, pressure and relative humidity. High-performance systems allow very fast changes to the conditions inside its test chamber. The ACC Chambers are suitable for Aviation and Weather Simulations. Chamber sizes are generally under 8 cubic feet.

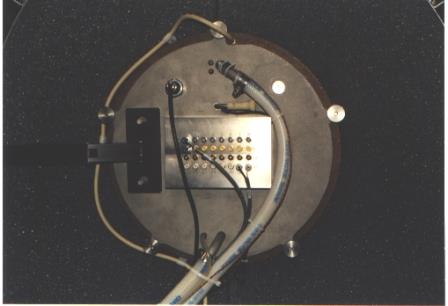

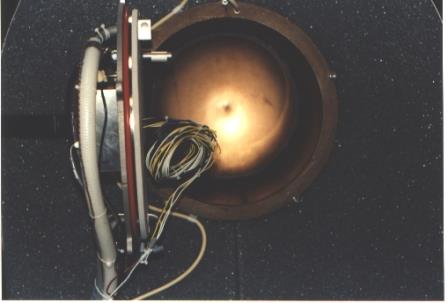

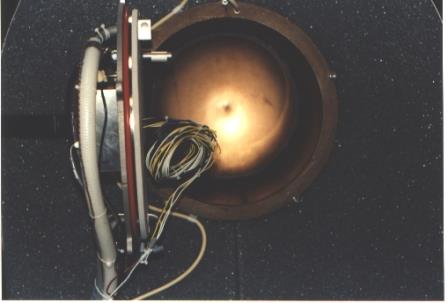

This test chamber contains numerous sensors and controls for monitoring your testing.

Such sensors may include temperature, Humidity, Pressure and other sensors.Altitude Control Chamber Specifications:

The altitude control chambers are typically customized to order. Customer needs determine the chamber design, specifications and features. Test parameters and the chamber specifications are engineered to deliver a quality system.

| Chamber Sizes | Options: | |

|---|---|---|

| (May not be required for some applications. Some items available through the | ||

| Standard Chamber | By special order such as 60.96cm x 60.96cm x 60.96cm. (24" x 24" x 24") | |

| Chamber size ranges | S1049cu cm to 1812278.18cu cm. (64cu " to 110592 cu ") | |

| Door Sizes | Application will determine the size. | |

| View ports | Application will determine the size. | |

| Environmental Range | (an example.) | |

| Temperature Maximum | 93C. (200F) (Typical) | |

| Temperature Minimum | -56C. (-70F) (Typical) | |

| Temperature Change Rate | 30C / minute. (both directions) (Typical) | |

| RH Minimum | Near 0% RH dependent on temperature and pressure. | |

| RH Maximum | Near 100% dependent on temperature and pressure. | |

| RH Change Rate | 20% / minute. (both directions) (Typical) | |

| Pressure Maximum | 1.15 Bars. (1.136atm) (862.5 torr) (33.96"Hg) | |

| Pressure Minimum | 50 mBars. (0.0194 atm) (37.5 torr) (1.476"Hg) | |

| Pressure Change Rate | Pressure 800 torr / min. Vacuum 760 torr to 100 torr 1 minute. 100 to 37.5 in 5 minutes. | |

| Chamber Construction | Test chamber constructed out of stainless steel. Various finishes are available. | |

| Chamber heat exchange | Provided by outer wall (external) or a heat plate (internal). |

| Option 1 | Air Circulation fans. | |

| Option 2 | Electronics feed-throughs. | |

| Option 3 | ESD protections. |

| Relative Humidity: | The standard setup is in a 22.8°C (73°F) room. | |

|---|---|---|

| Please contact us for details and suggestions. | ||

| Option 1 | Below 10% operations | |

| Option 2 | Above 95% operations - Condensing water may result in erratic results. |

| Temperature Control: | The standard setup exchanges heat to ambient room conditions using two stage chillers and electric heaters. Working Fluid: Dependent on conditions and chamber design. |

|---|

| Connections: | ||

|---|---|---|

| Power | Typically, 240 VAC 3 phase 50A 60Hz. | |

| Auxiliary inputs | Room condition recording. | |

| Vacuum pumps exhaust vent | Vented outside required. | |

| Optional | House vacuum if available, may be used. | |

| Nitrogen Supply | Nitrogen Purge. | |

| Air pressure | House Air Pressure may be used. | |

| Distilled water | Distilled water systems. | |

| Water drain | Water drain systems. | |

| Option 2 | Network connections. |

Dimensions:

Actual placement requires extra room around the units.

Test unit: Dependent on requirements.

Utility cart: Dependent on requirements.

System configuration and specifications may change without notice.

Altitude Control Chamber General Description

The ACC is an advanced test chamber used to simulate atmospheric conditions. Variables include controlling pressure, temperature and relative humidity for testing and evaluating properties of materials, processes and systems.

| Applications: | ||

|---|---|---|

| An electronics test lab certifying their product. | ||

| A research organization testing material properties. | ||

| An aerospace company simulating systems performance. | ||

| An electronics company testing for moisture effects. |

Test Types:

The environmental tests can be conducted using various environmental conditions.

Relative humidity profiles include steady state, steady state plus steps, square wave with ramp control (trapezoid.)

Chamber details:

The environmental chambers are barometric pressure compensated, to protect your long duration testing with changes in the weather. Significant errors can occur if this aspect is overlooked. RH probe calibrations can remain an issue, backup measuring systems may be needed if this is a critical parameter.

Extended duration testing, depending on cycle rate and amplitude may require pauses for maintenance on systems without redundant vacuum pumps and RH probes. Some high-performance systems may require the use of exotic (expensive) working fluids.

Distilled water utilized in the RH production will need to be replaced as water vapor is removed from the chamber by the vacuum pumps. Nitrogen purges may in addition be required for cold dry systems, as condensation will produce ice in some working fluids.

Electronics:

The ACC has numerous subsystems. The power is distributed through a high current sub-panel located in the utility cart. This power is utilized for such systems as the vacuum pumps, chillers and heaters. Numerous sensors allow the system to interface with the computer. The computer is a current generation running Microsoft® Windows operating system. The analog interface electronics uses 16-bit or higher precision.

Software:

The Microsoft® Windows® based HMI (Human Machine Interface) software controls the ACC. Concurrent multithreaded processes ensure superior level of performance and self-monitoring. The software is custom designed for this machine. Basic data storage is in the form of an ASCII text comma separated values (CSV) file that can be read by any software that can read a text file.

One option is to collect the data in a Microsoft® SQL Server® data storage system. The custom software also semi-automates sensor calibration. Data can be played back with a second program using a similar screen for review or demonstrations.

Please note:

The

Please contact us here at the

Sales E-mail: sales@CYCOGS.com

The

Liability Disclaimer:

The

Please specify your

Sales E-mail: sales@CYCOGS.com

The

The

The

Sales E-mail: sales@CYCOGS.com Support E-mail: support@CYCOGS.com