Differential Mobility

The

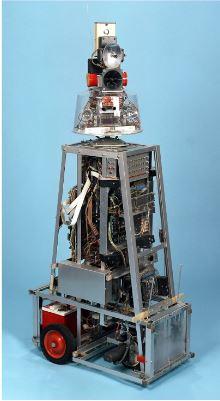

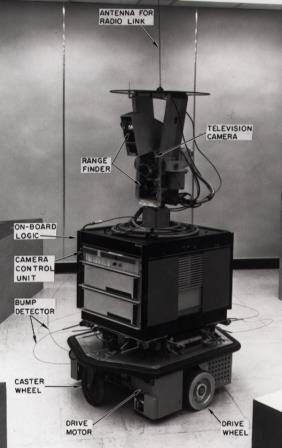

Mobile Robotics which operate on a floor or ground usually employ wheels. This is the case for Differential Mobility.

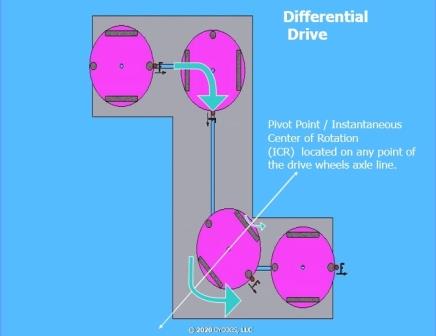

Differential Drive robots can rotate about any point located along the line imagined through the drive wheels axles,

be it inside or outside the robots’ body. Differential mobility uses two tracks or wheels, with the two tracks or the two or more drive wheels utilizing one propulsion motor per side (wheel or track). Two-wheel differential mobility robots are usually unstable and need help to maintain its balance. Four-wheel differential mode vehicles are more stable but are hard to steer.

Such stability measures/counter-reactions include implementing an active control inverted pendulum balance, tracks, side coupled wheels, idler wheels and / or skids.

Differential mobility is a minimalist system composed of a simple form design, using two drive wheels and one skid for balance.

Such stability measures/counter-reactions include implementing an active control inverted pendulum balance, tracks, side coupled wheels, idler wheels and / or skids.

Differential mobility is a minimalist system composed of a simple form design, using two drive wheels and one skid for balance.

Differential drive vehicles are widely used.

Most dual tracked vehicles are differential drives, with the tracks equivalent to wheels. There are 4-wheel skid steer loaders, such as the “Bobcat” model, which has 4 wheels, but on each side the wheels are connected as one and move together, acting as a virtual 2-wheel differential vehicle. The 4 wheels skid while turning, hence the name, “Skid Steer.” These are good for the outdoors and with small indoor robots as the wheels or tracks are typically fixed to the body, so as the wheels rotate to steer, so does the vehicle or robot body. Not very good for precise maneuvering and this skid steer design can inflict floor damage. If any doubt, ponder what would happen if a bull dozer or an Army tank turned around on the grass of your manicured lawn.

Straight away we include an equivalent vehicle, the two-wheel hand cart.

The two-wheel hand cart requires human balance and propulsion. During a tight pivot turn, note how the wheels rotate; one rotates clockwise, the other one rotates counter-clockwise. Plus, the wheels or tracks can turn at different (differential) speeds based on the turning radius.

The effective pivot point can be located on the axle center-line inside the wheel spacing on the axis, or outside of the wheel’s boundary on the axis.

The effective pivot point for a vehicle represents the center of the turn's radius, set on an imaginary line drawn though the wheels axle centerlines. In place rotations “Spin on a dime” are internal pivot points. A long sweeping turn uses an external pivot point. Another example is the Segway Personal Transporter.

The “Segway” uses active balance robotic two - wheel transport, with computer-controlled balance and human steering control inputs to provide mobility.

Another example is the Segway Personal Transporter.

The “Segway” uses active balance robotic two - wheel transport, with computer-controlled balance and human steering control inputs to provide mobility.

Now the iRobot Roomba floor vacuum uses two driven differential wheels and a wheeled skid for balance. And on the other end of the spectrum, is the 75-ton M1A3 Abrams Tank. This dual tracked vehicle is just a differential drive vehicle using two tracks operating as two wheels.

Most smaller farm tractors can operate in a quasi-differential mode.

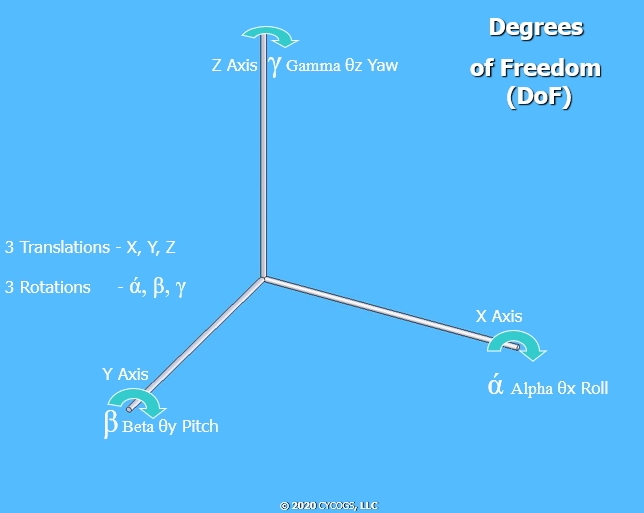

These tractors are equipped with split rear brakes, where each large rear wheel can be braked independently, such as skid steering, pivoting on a wheel or driving with minimal steering wheel input.These operate using two DoF in the X-Y directions in a 3D work space; therefore, they are not Holonomic.

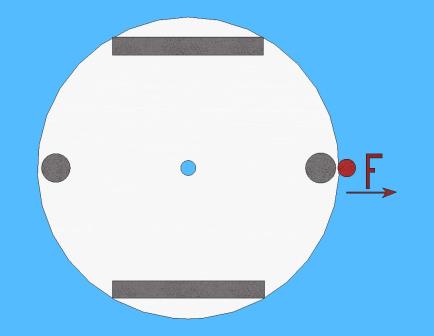

Here serves as an illustration showing a differential vehicle turning with both a pivot turns and a sweeping turn.

Note the F = Front of the vehicle / robot.

Here serves as an illustration showing a differential vehicle turning with both a pivot turns and a sweeping turn.

Note the F = Front of the vehicle / robot.

Learn more about AI Robotics with the

Contact: Send questions and comments about the Education on Differential Mobility by