CYCOGS AI Robotics Stories

Find some interesting

The CYCOGS Story.

The

While many people experience life while ignoring technology, few routinely and continuously study it. You may find yourself in a technology disadvantage if your usage and exposure are merely using a couple of apps on your smart phone and hanging out watching sports. If you follow this trend, new technology developments will become “scary magic.”

The

The  Some have criticized the

Some have criticized the The Big Robot Story.

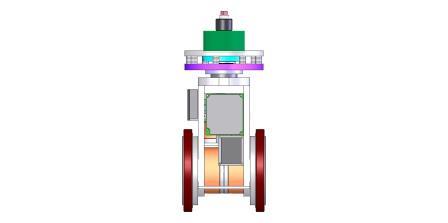

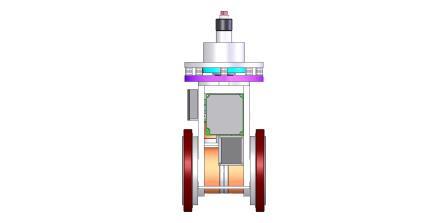

The CYCOGS ® Company robotics influenced its direction from the need and desire to manufacture and sell an extremely capable mobile robot system.

We decided to make this an indoor robot with exceptional capacity.

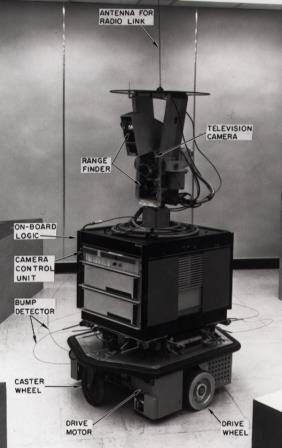

One of the early

Tracked mobility movement was too bulky and inefficient and lacks the ability to perform precise movements.

This left us with wheels.

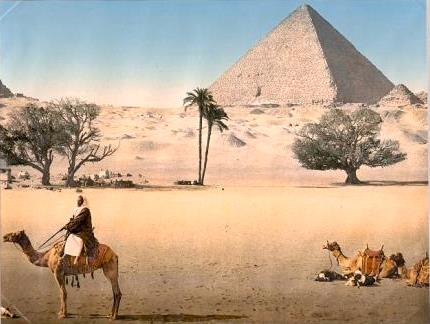

Wheels have been wielded in the past for thousands of years and will be used for thousands of years more in the future, for many legitimate reasons.

Tracked mobility movement was too bulky and inefficient and lacks the ability to perform precise movements.

This left us with wheels.

Wheels have been wielded in the past for thousands of years and will be used for thousands of years more in the future, for many legitimate reasons.

The CYCOGS ® Company is developing robotics that can perform substantial work, is mobile, and is able to lift and move things,

similar to a typical human’s capability.

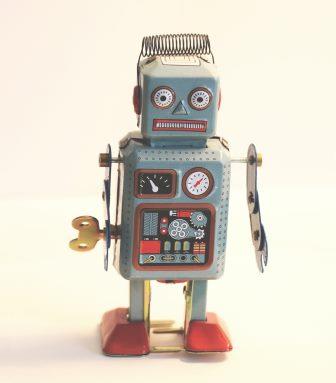

Unmistakably a 50-pound plastic robot with more in common with toys was out.

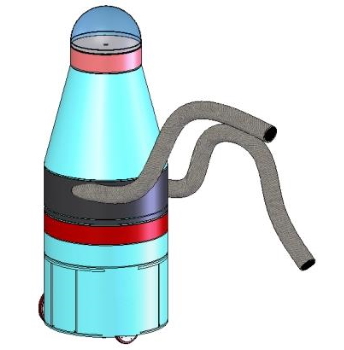

We decided to design and build a Medium Sized Robot (MSR™).

The next crucial issue was doorways.

Being able to transverse doorways then limited the maximum physical size. The long car like designs was finished.

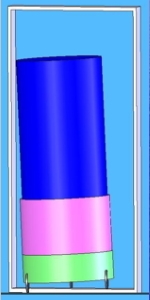

You have to go up. Exploiting this as a guideline, the most suitable shape was a tall round robot that provided the most volume for its size and environment.

This unfortunately forced the use of robotic arms into a complex problem.

We decided to design and build a Medium Sized Robot (MSR™).

The next crucial issue was doorways.

Being able to transverse doorways then limited the maximum physical size. The long car like designs was finished.

You have to go up. Exploiting this as a guideline, the most suitable shape was a tall round robot that provided the most volume for its size and environment.

This unfortunately forced the use of robotic arms into a complex problem.

For further details on the

For further details on the The Hi2WAM™ story.

With the

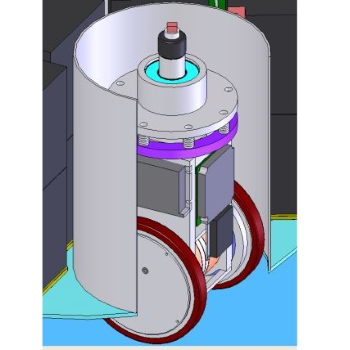

Differential Mobility could work by employing two large wheels, always tippy, rocking from the front to the rear.

Not particularly stable, and would result in high floor loading on those two wheels.

Synchronous Mobility is nice, using three wheels to define a plane.

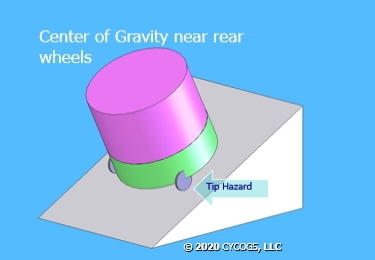

Almost perfect! But using synchronous robot mobility includes a limitation. Synchronous mobile designs cannot move in certain ways. Synchronous mobility equipped robots cannot pivot on a wheel, nor rotate its body. If you have a robotic arm picking up some item, with no ability to orient the wheel geometry for best weight distribution, your robot may be tip-over prone.

Mechanum wheels are not terribly effective in this case also, too much maintenance, vibration and floor wear/damage, and the list goes on.

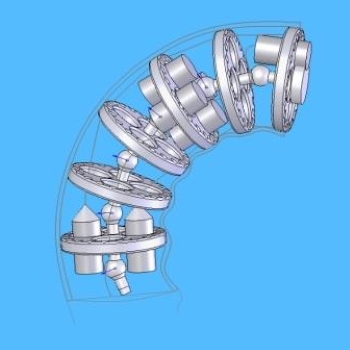

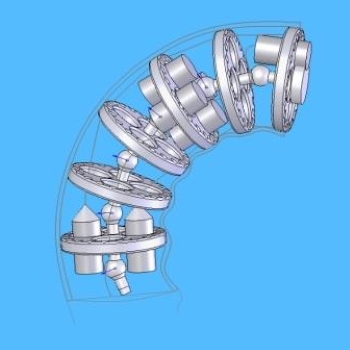

The solution to this problem is to use the wheeled holonomic mobility drive type and its enhanced movement abilities.

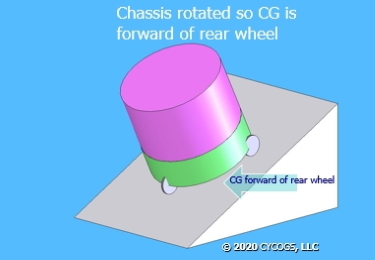

Holonomic mobility can mimic the motion capabilities of the differential and synchronous drives, plus more! Holonomic mobility type vehicles are able to move in any way the robot needs. This mobility ability also enables a robotic arm equipped mobile robot to rotate its body, placing a wheel under/closer to the load. Such abilities allow the tip over issue to be managed. Directly using a three wheeled holonomic mobile robot represents a great solution to this mobility problem.We wanted to keep the robots floor loading weight lower to minimize the buildings floor wear and avoid damage. You can drop the per-wheel floor loading in half if you double the number of wheels! With the three wheel assemblies equally spaced in the robot, doubling the wheel count furnishes you with six wheels, and if driven, six-wheel drive! Using six wheels additionally allows the use of smaller diameter wheels, and a resulting smaller vehicle volume, compared to larger two and three-wheel designs.

But CYCOGS had a balance and a collision problem.

Our tall robot needed to lean or correct its stance for uneven flooring and floor transitions, especially in doorways.

And when the robot arms lift a heavy object, a means to shift the center of gravity (CG) would be helpful.

Plus, we wanted to measure the load on each wheel for tip and balance monitoring.

The CYCOGS ® Company solution was to design an active suspension system to adjust the height of each wheel pair.

We directly have height control, with an active suspension!

We know we could fabricate it into an integrated base, but that base would be complex and routine maintenance would be slow and problematic.

As a result, we designed each wheel pair as a removable wheel assembly module and gave the holonomic wheel assembly some local intelligence and control and called it the

As a result, we designed each wheel pair as a removable wheel assembly module and gave the holonomic wheel assembly some local intelligence and control and called it the

For further details on the

For further details on the For a tutorial covering the

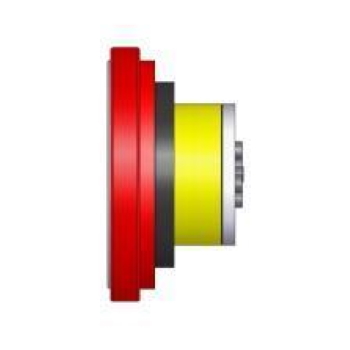

The WA™ Story.

When the

The

Some may think, “just use a Harmonic gear reduction and a short motor.” Nice thought, if you don’t mind ending up being 10-14 inches wide.

We did it in under 4” (about 95mm)!

Some may think, “just use a Harmonic gear reduction and a short motor.” Nice thought, if you don’t mind ending up being 10-14 inches wide.

We did it in under 4” (about 95mm)!

To accomplish this short length,

To accomplish this short length, The SNARM™ Story.

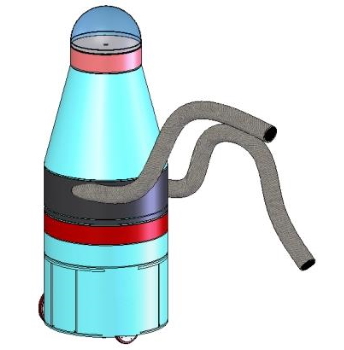

With the robotic mobility issues under control, the

The

Standard industrial arms have the capacity and speed issues sorted out.

But these arm types provided a terrible fit for our working envelope, power use, size and weight requirements.

Absolute arm repeatability is not much use as the mobile robot could be shifting on a carpet or moving across the floor or adjusting its attitude.

This mushiness in its environment diminished the advantage of fixed robotic arm repeatability and accuracy.

Standard industrial arms have the capacity and speed issues sorted out.

But these arm types provided a terrible fit for our working envelope, power use, size and weight requirements.

Absolute arm repeatability is not much use as the mobile robot could be shifting on a carpet or moving across the floor or adjusting its attitude.

This mushiness in its environment diminished the advantage of fixed robotic arm repeatability and accuracy.

The

With protruding robotic arms, the robot would be limited in its mobility in tight locations. And the robots job requirements required the use of two arms at once, limits any fixed mounting locations. We could develop a shorter robot and place the arms on the top. Top mounted robotic arms would allow limited arm access if something was on the floor, and that nevertheless had the problem of using both arms at once for some tasks. What to do?

We pondered what kind of mobile robot chassis would resolve this? After much R&D,

The result, the CYCOGS ® Company developed the

hybrid-rotating snake arm platforms

located inside the robot!

With this robot design development, one type of robot arm fell into place.

The

multi-segmented snake arms!

Normally these snake arms are long and not at all suitable for storage or mobile robotics use. With our rotating platform, the arms simply curl up upon the rotating platform!

In this manner, the arms can be stored inside the robot, no substantial parts sticking out!

With this robot design development, one type of robot arm fell into place.

The

multi-segmented snake arms!

Normally these snake arms are long and not at all suitable for storage or mobile robotics use. With our rotating platform, the arms simply curl up upon the rotating platform!

In this manner, the arms can be stored inside the robot, no substantial parts sticking out!

The

Now CYCOGS has an internally stored, dual-hybrid snake arm system, plus with a huge 365-degree floor to ceiling working envelope!

Additionally, the system is compliant and strong enough for

use around humans

like picking someone up off the floor and putting them into bed.

We at the For further details on the

For a tutorial about the

For a tutorial about the Our CGM™ Story.

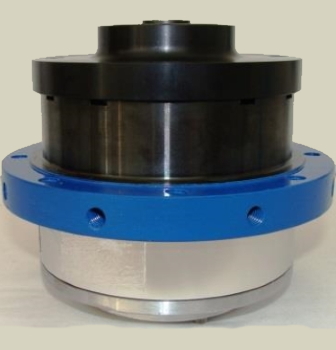

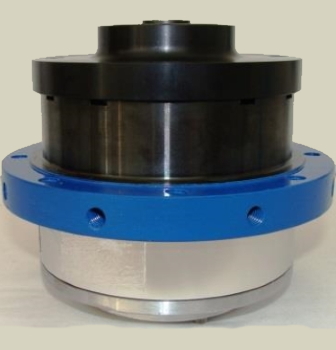

The

Compact Gear Motor (CGM™)

design was

initially developed for the CYCOGS ®

brand Hi2WAM™ product.

We needed a compact motor and gear reduction to ensure the orientation of the dual wheels for steering purposes, as some movement types required absolute controlled movements,

and any floor slippage or obstacles could throw off the movements.

We had developed the

Orientation drive and the Wheel Assembly

(WA™) for the Hi2WAM™

and determined these designs minimal size and generous capacity was perfect for this orientation positioning.

The electric gear reduction drive was not infact a separate product yet.

As you may have read from the SNARM™ story, we also needed a compact gear motor to move the segments of our snake arms.

Traditional gearing, including harmonic gearing was still too bulky, and with our compliant arms, absolute repeatability and zero backlash was not an issue.

We had developed a compact gear motor based off the WA™ for orienting the Hi2WAM’s wheels, and found that with some modifications,

we could implement the same basic drive on the snake arm segments.

With an eye to utilizing common parts, we had created the

As you may have read from the SNARM™ story, we also needed a compact gear motor to move the segments of our snake arms.

Traditional gearing, including harmonic gearing was still too bulky, and with our compliant arms, absolute repeatability and zero backlash was not an issue.

We had developed a compact gear motor based off the WA™ for orienting the Hi2WAM’s wheels, and found that with some modifications,

we could implement the same basic drive on the snake arm segments.

With an eye to utilizing common parts, we had created the

The SRing™ Story.

The CYCOGS ® brand

MSR™ robot (Medium Sized Robot)

needed to perceive its world.

Many traditional robots have one, two or more video cameras that are ether fixed or have limited movement.

We pondered this sensing problem.

We could throw a gazillion sensors all over its body to cover and sense every angle or decouple the sensors from the fixed body by

rotating the sensors.

Some sensors are inexpensive (cheap) and some are enormously expensive (IR cameras and LIDAR sensors)

and if we rotated the sensors, we had a means to expand a sensors field of view (FoV).

We could throw a gazillion sensors all over its body to cover and sense every angle or decouple the sensors from the fixed body by

rotating the sensors.

Some sensors are inexpensive (cheap) and some are enormously expensive (IR cameras and LIDAR sensors)

and if we rotated the sensors, we had a means to expand a sensors field of view (FoV).

Consequently, the

Consequently, the  This concludes the story of some of our design choices. We feel this is the best solution available. Stay tuned for more stories.

This concludes the story of some of our design choices. We feel this is the best solution available. Stay tuned for more stories.

Contact: Send questions and comments about this web site to the