Synchronous Drive Mobility

The

Mobile Robotics which operate on a floor or ground usually employ wheels.

This is the case for Synchronous Mobility.

With a synchronized mobility vehicle, all of the wheels rotate and steer together in a synchronized motion.

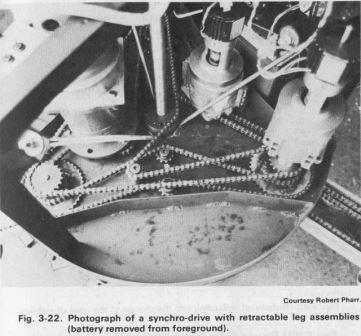

The wheels are all steered and propelled in a synchronous fashion. The synchronous mobility drive typically requires two motors with distributed mechanical components for the propulsion and steering forces. (steering and propulsion coupling is typically done gears, chains, belts or occasionally electrically)

While synchronous mobility is simpler to control than a differential drive, where using differential mobility requires the vehicle or Robot to compute each wheel’s velocity for movement.

Synchronous mobility control is just steering angle and wheel velocity.

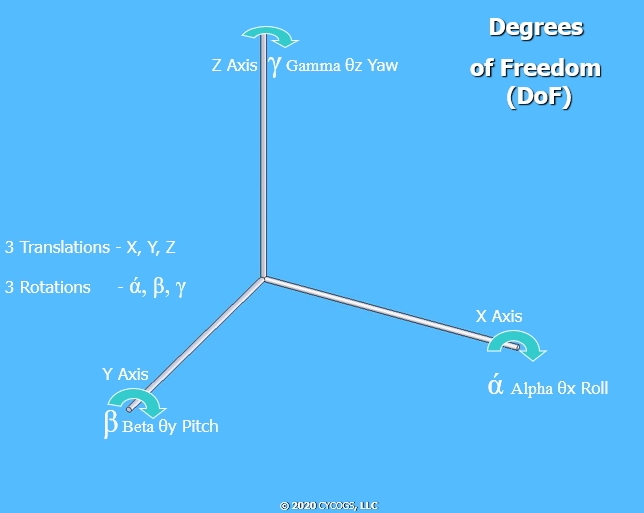

Synchronous drive mobility is two - DoF mobility (X-Y), highly maneuverable, and can move in any X and Y directions.

The synchronous mobility type operates using two DoF in the X-Y directions in a 3D work space; hence, they are Not Holonomic. Using synchronous mobility lets a Robot run simpler program code for most movements.But the problems occur when a collision or wheel slippage builds up, even complex maneuvers to correct its position may not restore the proper orientation of the vehicle/ Robot body.

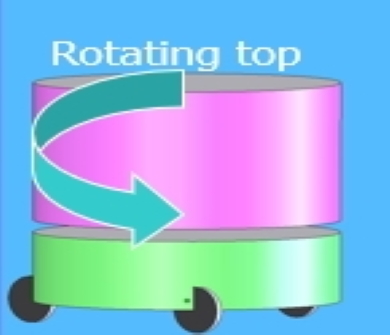

The overall body orientation in space represents a problem as the vehicle and or Robot cannot rotate about its axis or other interior or exterior points. (non-holonomic) Some synchronous mobility implementations have a rotating body section that can point in the direction of travel, but it is limited by slip rings or connection cables.

Synchronous drives also feature intrusive mechanical systems to couple and synchronize the movements. These mechanical components occupy prime Robot interior volume.

Another issue is if one wheel gets stuck, hung up or locked. All the propulsion and steering forces could be applied to that one wheel, and its ether gets unstuck, or something breaks. In Robotics, differential robots are used more often than synchronous mobility Robots, namely due to the tradeoffs of costs and mobility.

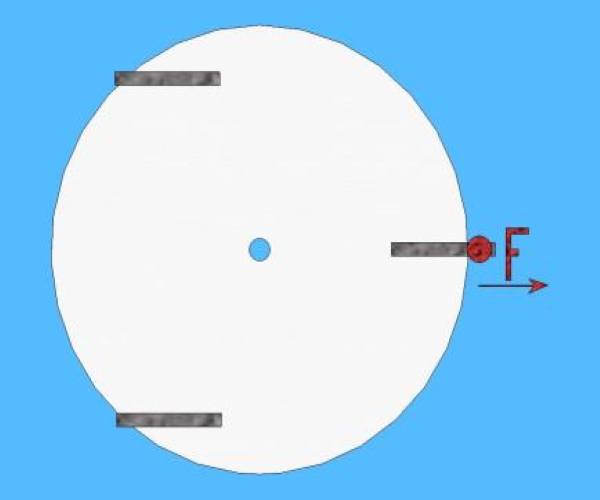

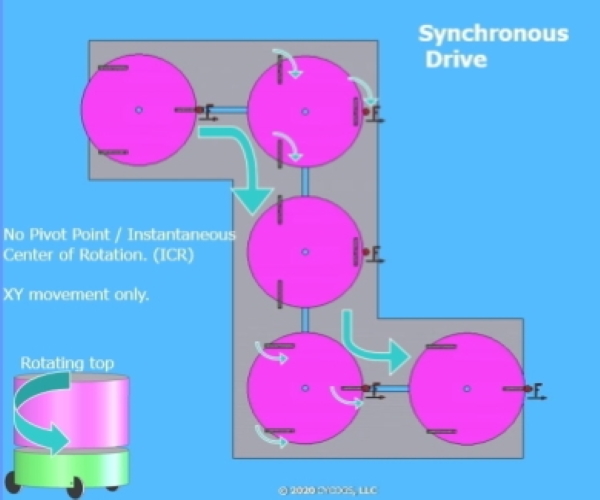

An illustration of a synchronous mobility Robot movements. Note the F = Front of the Robot,

it never changes direction as the robot moves.

The synchronous mobility Robot can only move in the X and Y directions.

If used with a docking station, any skidding, slipping or accumulated drift will create an alignment failure.

An illustration of a synchronous mobility Robot movements. Note the F = Front of the Robot,

it never changes direction as the robot moves.

The synchronous mobility Robot can only move in the X and Y directions.

If used with a docking station, any skidding, slipping or accumulated drift will create an alignment failure.

Learn more about AI Robotics with the

The

Contact: Send questions and comments about the Education on Synchronous Mobility by