CYCOGS ® brand, STFA Small VCA System

Our Test equipment technology includes our STFA Small VCA System material test system.

The STFA Small VCA Thin Film Analyzer is a capable material test System.

Such sensors may include load, extensometers, vision, and other sensors. General Description

General Description

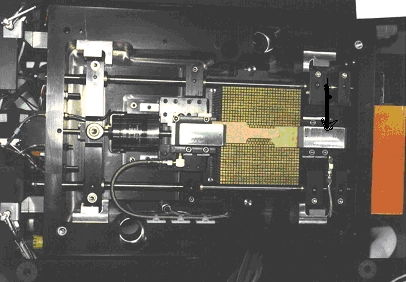

The STFA is an advanced paper test instrument used for testing and evaluating mechanical properties of planar type materials like paper, plastics, corrugated, composites, textiles, elastomers, etc.

The load frame (load control) applies a mechanical force and measures the resulting stress.

An Extensometer provides strain data allowing load related data analysis.

Applications: |

||

|---|---|---|

| A paper test lab certifying their product. | ||

| A research organization testing recycled material properties. | ||

| A packaging company simulating corrugated box performance. | ||

| A fabric manufacturer testing strengths. |

The tests can be conducted under various environmental conditions. Relative humidity is uncontrolled, the RH and Temperature conditions are passive based on the room’s environment.

The test types remain as follows:

Test Types: |

||

|---|---|---|

| Load | Such as tensile, compression, creep and stiffness. | |

| Short column | (edgewise compressive corrugated fiberboard - requires short column fixtures.) |

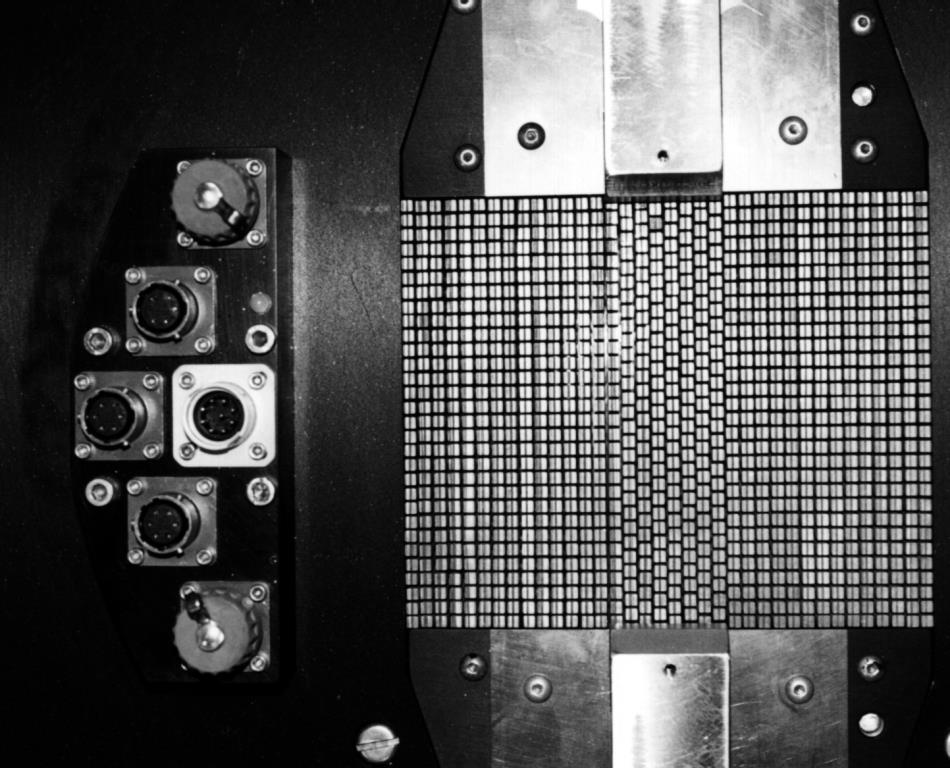

Electronics:

The STFA has few subsystems.

The power is distributed through the primary unit. Basic sensors allow the real world to interface with the computer. The computer is a current generation running Microsoft® Windows®. The analog interface electronics uses 16-bit or higher precision.

Software:

The Microsoft® Windows® based HMI (Human Machine Interface) software controls the STFA.

Concurrent multithreaded processes ensure a superior level of performance and self-monitoring. The program running on Microsoft® Windows® is custom designed for this machine. Basic data storage is in the form of an ASCII text comma separated values (CSV) file that can be read by any software that can read a text file. The custom software semi-automates sensor calibration. Data can be played back with a second program using a similar screen for review or demonstrations.

Other Information:

The internal load frame uses manual clamps that are adjustable.

The vacuum system provides sample restraint and air flow.

Maximum air flow results in minimal restraint.

The STFA consists of one unit, with other components like the computer.

Key Benefits: |

||

|---|---|---|

| In-plane compression testing. | ||

| Precision load system using load control. | ||

| Multitude of test types. | ||

| Modern computer control. |

Sample Sizes: |

||

|---|---|---|

| Standard load-based test | 3.08cm x 15.3cm (1.21" x 6.02") By special order. (3.08cm X 17.78cm) | |

| High load test | May require a necked (dog bone) sample, depending on expected load: Necked down to 1.50 cm. (0.59") | |

| Minimum thickness | The actual material properties will determine the minimum thickness. | |

| Maximum thickness | 3mm (0.12"), depending on clamp foot design. | |

| Short column test (Option) | 5.1cm X 3.2cm (2" x 1.25".) This sample size may vary depending on ultimate load potential, flute type, etc. | |

| Optional | Pass through sample preparation punches. |

Load Range: |

||

|---|---|---|

| Internal load frame capacity | ±1.3344kN. (300 lbf.) | |

| A/D conversion | 16 bits resolution. | |

| Load control | 16 bits resolution. NOTE: this device's cross head motion uses load control. | |

| Load ramp rates | User selected; computer generated. | |

| Calibration | 444.8 N (100 lbf.) load ring standard. | |

| Optional | Short column test fixture. |

Extensometer: |

A precision extensometer is used for motion sensing. | |

|---|---|---|

| Typical setups | 25.4mm (1") gage length 10% extensometer. | |

| A/D conversion | 16-bit resolution. | |

| Option 1 | 25.4mm (1") gage extender for 5% operations. | |

| Option 2 | 1 - 2mm (micron level) measurement. | |

| Option 3 | Optical measurements. |

Software:

Optional Microsoft® SQL Server® data storage.

Relative Humidity:

The standard setup is in a 22.8°C (73°F) 50% room.

The system can be placed in other environmental conditions, such as a 20% room or a 90% room.

Please contact us for details and suggestions.

Option 1 Below 10% operations.

Option 2 Above 95% operations - Condensing water may result in erratic results.

Temperature Control:

The standard setup exchanges heat to ambient room conditions.

Standard 22.8°C (73°F); 50% RH.

Connections: |

||

|---|---|---|

| Power | Typically, 120 VAC one phase 10A 60Hz. | |

| Auxiliary inputs | Room condition recording. | |

| Vacuum pump exhaust vent | Vented outside preferable. | |

| Option 1 | House vacuum if available, may be used. | |

| Option 2 | Network connections. |

Please note:

Please note:

The

System configuration and specifications may change without notice.

Please contact us here at the

Sales E-mail: sales@CYCOGS.com

The

Liability Disclaimer:

The

Please specify your

Sales E-mail: sales@CYCOGS.com

The

The

The

Sales E-mail: sales@CYCOGS.com Support E-mail: support@CYCOGS.com