CYCOGS ® brand, VCA TFA Vacuum Compression Apparatus, Thin Film Analyzer material technology testing platform

contain numerous sensors, and additional sensors can be embedded. Such additional sensors may include optical moisture content, moir'e optical pattern analyzers and other sensors that may be needed.

General Description

The VCA TFA is an advanced paper test instrument controlling relative humidity for testing and evaluating mechanical properties of planar type materials.

Such materials include paper, plastics, corrugated, composites, textiles, elastomers, etc. The load frame (load control) exerts mechanical force and measures the resulting stress. Extensometers provide strain data allowing data analysis of yield, energy, modulus and Poisson's ratio.

Sample measurements include the loads, and the X, Y, and Z deflections.

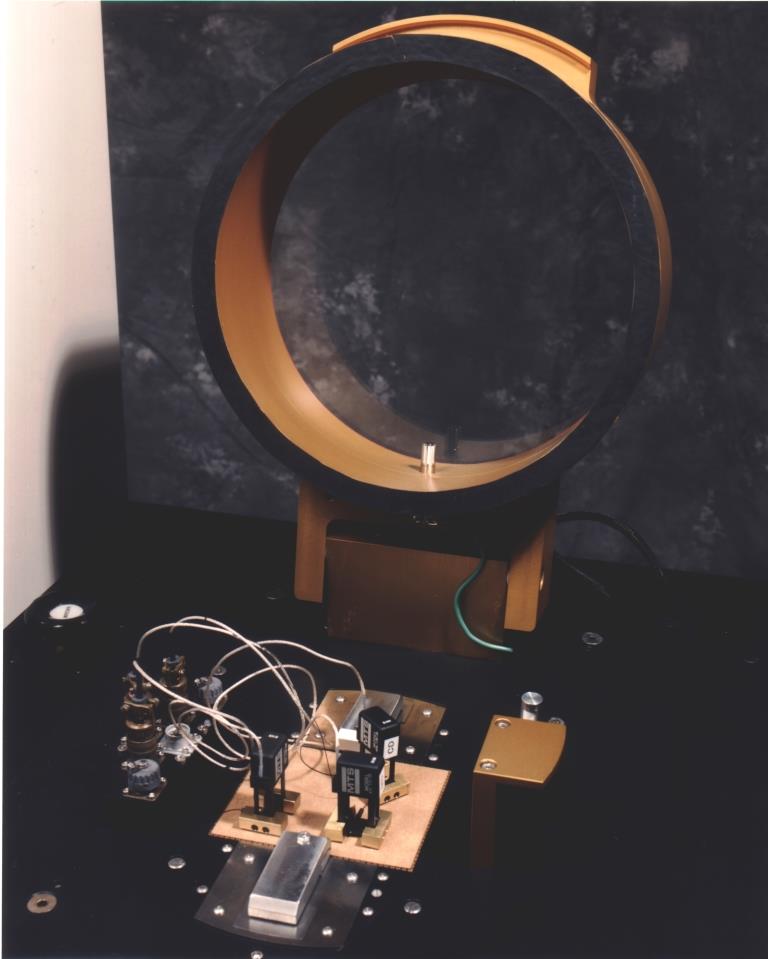

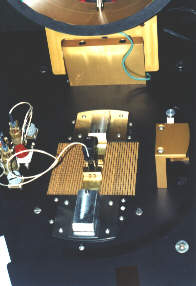

Dimensional stability test setup on paper with three extensometers.

Dimensional stability test setup on paper with three extensometers.

Applications: |

||

|---|---|---|

| A paper test lab certifying their product. | ||

| A research organization testing recycled material properties. | ||

| A packaging company simulating corrugated box performance. | ||

| An electronics company testing for moisture effects. | ||

| A fabric manufacturer testing moisture related strengths. | ||

| A publisher solving ink registry problems caused by dimensional changes during printing. | ||

| An adhesive label manufacturer analyzing humidity effects on glued paper. |

Test Types

The tests can be conducted under various environmental conditions.

Relative humidity profiles include steady state, steady state plus steps, square wave with ramp control (trapezoid), sine wave, saw-tooth (triangle) wave, swept frequency waves.

Custom profiles like actual recorded data from a process or warehouse can be used as a control profile.

| The test types include the following: | ||

|---|---|---|

| Load | Tensile, compression, creep, stiffness, biaxial (required biaxial test frame). | |

| Short column | (edgewise compressive corrugated fiberboard) (required short column fixtures). | |

| Dimensional stability | (four axis, X, Y, XY and Z). | |

| Moisture migration | Curl, air permeability studies. |

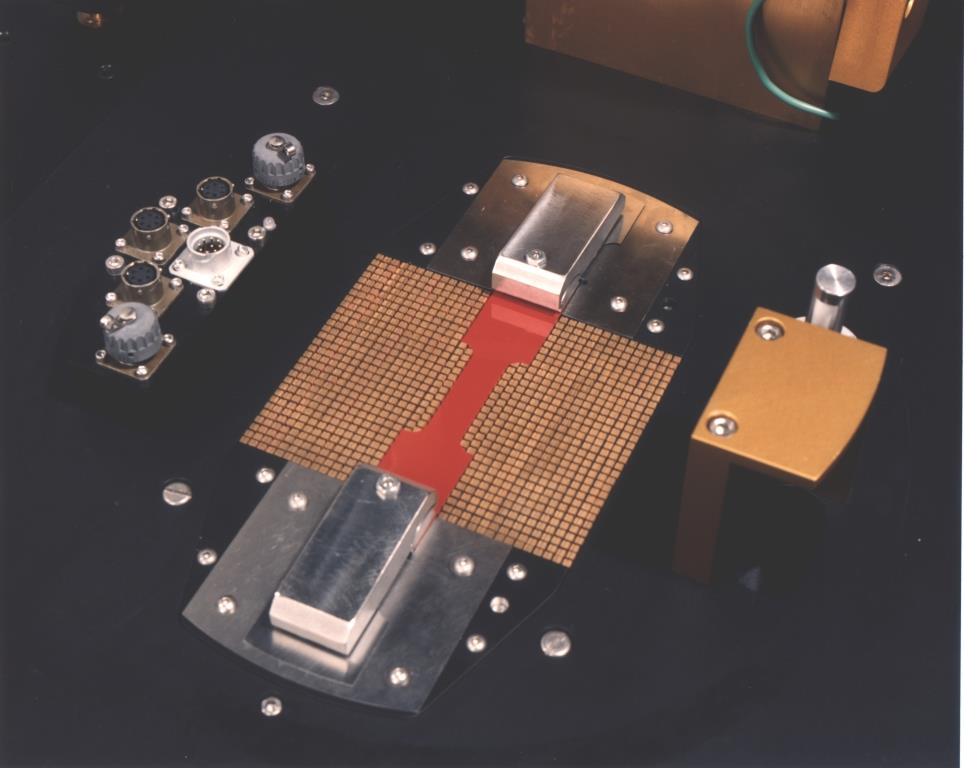

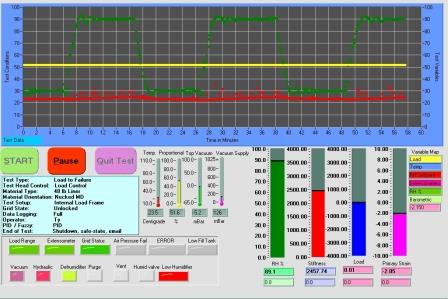

Load test of plastic sample in tension.

Load test of plastic sample in tension.

Electronics:

The TFA VCA platform has numerous subsystems.

The power is distributed through a high current sub-panel located in the utility cart.

The test unit, in addition, contains an uninterruptible power supply, computer and electronics.

Numerous sensors allow the real world to interface with the computer.

The computer is a current generation running Microsoft® Windows®.

The analog interface electronics uses 16-bit precision.

The TFA VCA platform has numerous subsystems.

The power is distributed through a high current sub-panel located in the utility cart.

The test unit, in addition, contains an uninterruptible power supply, computer and electronics.

Numerous sensors allow the real world to interface with the computer.

The computer is a current generation running Microsoft® Windows®.

The analog interface electronics uses 16-bit precision.

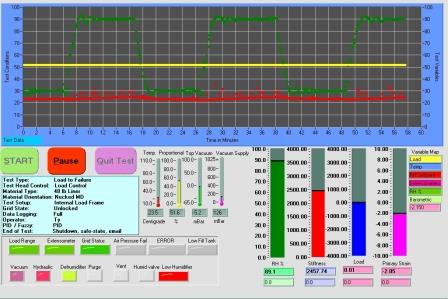

System Software:

The Microsoft® Windows® based HMI (Human Machine Interface) software controls the TFA. Concurrent multithreaded processes ensure a high level of performance and self-monitoring. The program running on Microsoft® Windows® is custom designed for this machine. Basic data storage is in the form of an ASCII text comma separated values (CSV) file that can be read by any software that can read a text file. The custom software semi-automates sensor calibration. Data can be played back with a second program using a similar screen for review or demonstrations.

Other Information:

The internal load frame uses hydraulic clamps that are pressure adjustable.

The external load frame (biaxial) uses glue tabs.

The vacuum system provides sample restraint and air flow.

Maximum air flow results in minimal restraint.

The VCA TFA consists of two units.

The first component is called the Test Unit.

The second unit is named the Utility Cart.

The Utility Cart contains heat and noise generating devices like motors, pumps, dehumidifier, etc.

This device can be placed remotely from the Test Unit in the utility cart.

The two units are connected with umbilical cables and pipes.

The separation distance between the two components depends on the application and the installation configuration.

Key Benefits: |

||

|---|---|---|

| In-plane compression testing. | ||

| Precision load system using load control. | ||

| Multitude of test types. | ||

| Exceptional single pass RH control. | ||

| Modern computer control. |

Sample Sizes: |

||

|---|---|---|

| Dimensional Stability | 14.1cm x 11.7cm (5.55" x 4.6" max). | |

| Standard Load-Based test | 3.08cm x 15.3cm (1.21" x 6.02.") | |

| High Load test | May require a necked (dog bone) sample, depending on expected load: necked down to 1.50 cm (0.59.") | |

| Minimum Thickness | The actual material properties will determine the minimum thickness. | |

| Maximum Thickness | 3mm (0.12"), depending on clamp foot design. | |

| Short Column test | 5.1cm X 3.2cm (2" x 1.25".) This sample size may vary depending on ultimate load potential, flute type, etc. |

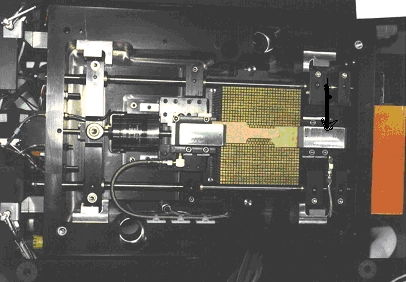

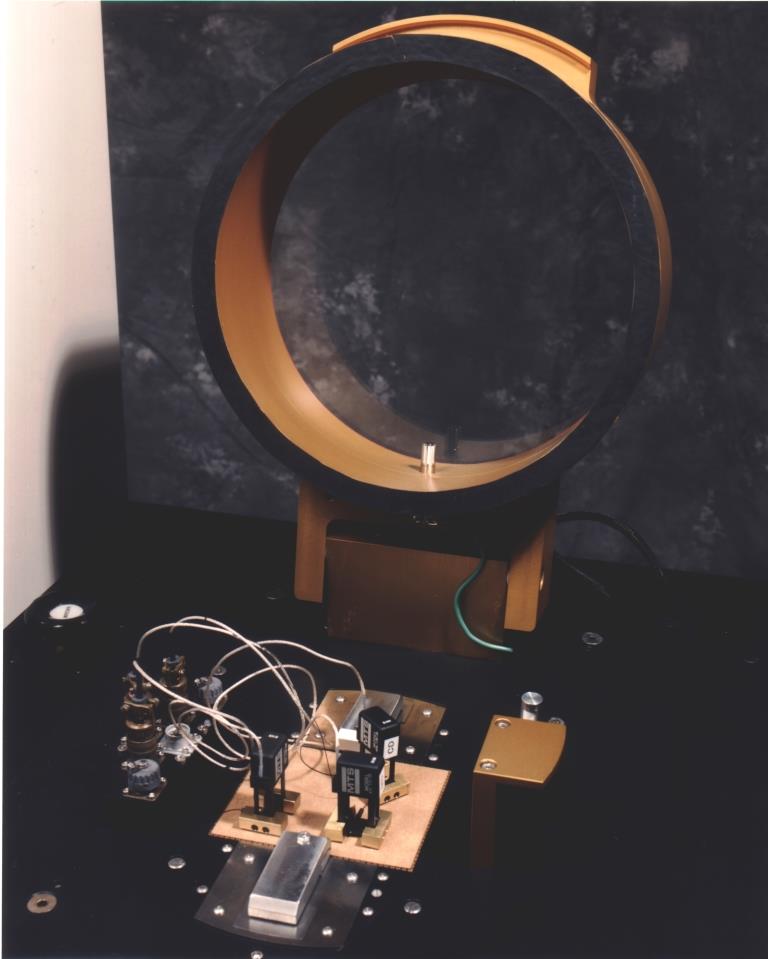

VCA TFA Load test setup.

VCA TFA Load test setup.

Load Range: |

||

|---|---|---|

| Internal Load Frame capacity: | ±1.3344kN (300 lbf.) | |

| External Load Frame (Biaxial) capacity: | ±444.8 N (100 lbf.) | |

| Load Control: | 16 bits resolution. NOTE: this device's cross head motion uses load control. Load ramp rates User selected; computer generated. | |

| Calibration: | 444.8 N (100 lbf.) load ring standard. | |

| Option 1: | Biaxial test frame and fixture (external load frame). | |

| Option 2: | Short column test fixtures. | |

| Option 3: | Pass through sample preparation punches. |

Extensometers: |

Precision extensometers are used for motion sensing. | |

|---|---|---|

| Most load tests: | One or two are used. | |

| Dimensional stability test: | Uses three extensometers. | |

| Typical setups: | 25.4mm (1") gage length 10% extensometers. | |

| A/D conversion: | 16-bit resolution. | |

| Z direction data: | Uses a DVRT sensor. | |

| Option 1: | 25.4mm (1") gage extender for 5% operations. | |

| Option 2: | one to two mm (micron level) Z direction or precision measurements. | |

| Option 3: | Optical measurements. |

Test Software: |

||

|---|---|---|

| Option 1: | Microsoft® SQL Server® data storage. | |

| Option 2: | Internet enabled remote monitoring and email event notification. | |

| Option 3: | Robotic specimen loading. |

Relative Humidity:

The standard setup in a 22.8°C (73°F) 50% room will control (depending on proper test setups) 25% to 95% RH (non-condensing).

A typical accelerated load test may use a 10 minute 30%-90% sinusoid control ramp.

Faster square wave cycles are possible; however, the system response may not follow the square wave input within the 2% target.

| Relative Humidity: | ||

|---|---|---|

| Option 1: | Below 10% operations. | |

| Option 2: | Above 95% operations - Condensing water may result in control issues. | |

| Option 3: | Optical moisture sensor. |

VCA TFA Test Types:

The environmental tests can be conducted using various environmental conditions.

Relative humidity profiles include steady state, steady state plus steps, square wave with ramp control (trapezoid).

| Temperature Control: | The standard setup exchanges heat to ambient room conditions. | |

|---|---|---|

| Standard: | 22.8°C (73°F); 50% RH. | |

| Option 1: | Stabilized to 22.8°C (73°F). | |

| Option 2: | User defined temperature setpoint, e.g. 10°C (50°F). |

Connections: |

||

|---|---|---|

| Power | Typically, 240 VAC 3 phase 30A 60Hz. | |

| Water Input | (daily) (distilled preferred) 0-20 Liters (0-5.3 gallons). | |

| Waste Water drain | (daily) (excess working and dehumidifier drain) 0-11 Liters (0-2.9 gallons). | |

| Auxiliary Inputs | Room Condition recording. | |

| Vacuum Pump Exhaust vent | Vented Outside preferable. | |

| Utility Cabinet Cooling vent | Vented Outside preferable. | |

| Option 1 | House Air Pressure (if available, else air compressor required). | |

| Option 2 | Network connection. |

Dimensions: |

||

|---|---|---|

| Wall Placement | Requires extra room around the units | |

| Test Unit | 1.58m L x 0.914m W x 1.52m H (62"L x 36"W x 60"H) | |

| Utility Cart | 1.96m L x 0.84m W x 0.86m H (77"L x 33"W x 34"H) |

The VCA TFA Thin Film Analyzer main test cabinet and Utility Cart Unit.

The VCA TFA Thin Film Analyzer main test cabinet and Utility Cart Unit.

VCA TFA Links of Interest: |

||

|---|---|---|

| This is a modest collection of related internet links. | ||

| The Bureau of Engraving and Printing (BEP) | ||

| USDA Forest Service Forest Products Lab. (FPL) | ||

| Scion Forest Research Institute | ||

| Isthmus Engineering and Manufacturing COOP | ||

| TAPPI | ||

| University of Maryland CALCE | ||

| Korutest Chalmers DST (Dynamic Stiffness Tester) |

Please contact us here at the

Sales E-mail: sales@CYCOGS.com

The

System configuration and specifications may change without notice.

Liability Disclaimer:

The

Please note:

The

Please specify your

Sales E-mail: sales@CYCOGS.com

The

The

The

Sales E-mail: sales@CYCOGS.com Support E-mail: support@CYCOGS.com